5 Common Problems with Kohler Horizontal Shaft Engines and How to Fix Them

Share

Kohler horizontal shaft engines are popular for their durability and performance in small machines, including lawnmowers, generators, and utility vehicles. However, like any engine, they are not immune to issues. Understanding these common problems can save you time and money while keeping your engine in top shape. For professional repairs and maintenance, check out our engine service page.

Common Problems with Kohler Horizontal Shaft Engines

1. Starting Issues

Starting issues are among the most common problems with Kohler horizontal shaft engines, and they can be particularly frustrating when you need your equipment to work immediately. These problems often arise due to several factors, including a dead or weak battery, faulty spark plugs, a clogged carburetor, or dirty fuel. A poorly maintained ignition system can also contribute to the problem. Environmental factors like extreme cold can exacerbate starting issues, making routine checks even more important.

To fix these issues, start by testing the battery using a multimeter. Ensure the voltage is around 12.6 volts; if not, recharge or replace the battery. Next, inspect the spark plugs. Look for signs of wear, such as corrosion or carbon buildup, and replace them if necessary. Carburetor problems can often be resolved by removing and cleaning it with a carburetor cleaner. If your fuel lines are clogged, flush them thoroughly, and replace damaged lines to ensure proper fuel flow.

Keeping a regular maintenance schedule can help prevent these problems. Clean or replace air and fuel filters frequently, and use high-quality fuel to reduce debris buildup. For professional servicing or parts, explore our engine service page.

2. Engine Overheating

Overheating is a serious issue that can severely damage your Kohler horizontal shaft engine if left unaddressed. It often results from poor ventilation, clogged cooling fins, low oil levels, or excessive workload on the engine. Environmental factors, such as high ambient temperatures and dusty conditions, can also worsen overheating. Prolonged overheating can lead to warping, seizing, or even cracking of engine components.

To fix this problem, start by cleaning the cooling fins. Use compressed air or a soft brush to remove accumulated debris that may restrict airflow. Next, check the engine's oil levels and quality. Low or dirty oil can cause excessive friction, leading to overheating. Replace the oil with a Kohler-recommended product to maintain optimum performance. Reducing the workload on the engine, such as avoiding extended operation under heavy loads, can also prevent overheating.

Regular maintenance plays a crucial role in keeping the engine cool. Replace air filters regularly to ensure proper airflow and clean the engine’s exterior to prevent dirt buildup. If overheating persists despite these measures, it might indicate deeper issues requiring professional assistance. For replacement parts or expert advice, explore our horizontal shaft engines collection.

3. Loss of Power

A Kohler horizontal shaft engine losing power can be frustrating and impact your equipment's performance. This issue typically arises due to dirty air filters, blockages in the fuel system, or worn-out internal components like pistons or valves. Inadequate fuel delivery or poor compression can also result in a noticeable drop in power output.

To address this, begin with a visual inspection of the air filter. If it’s clogged or excessively dirty, clean it or replace it with a new one. Next, check the fuel system for blockages. Clogged fuel lines or filters can disrupt the fuel flow, starving the engine. Flushing the lines and replacing the filter can help restore proper fuel delivery. Examine the engine’s internal components for wear, and replace any that are damaged.

Preventive maintenance is key to avoiding power loss. Use high-quality fuel and oil to reduce wear and tear on engine components. Regularly inspect and replace spark plugs to maintain consistent ignition. By keeping the engine clean and ensuring optimal operating conditions, you can prevent significant performance drops. For engine upgrades or alternative options, visit our vertical shaft engines collection.

4. Oil Leaks

Oil leaks are not only messy but can also lead to severe engine damage if left unresolved. They are commonly caused by worn-out gaskets, damaged seals, or even cracks in the engine casing. Overfilling the oil tank or using incorrect oil grades can also contribute to leaks by creating excess pressure within the engine.

To resolve oil leaks, start by locating the source of the problem. Check the gaskets and seals for visible damage and replace them as needed. Inspect the engine casing for cracks and, if found, consult a professional for repair or replacement. Ensure you’re using the right type and quantity of oil as recommended in the engine manual. Overfilling the tank can increase pressure, pushing oil out through weak points.

Preventing oil leaks involves routine checks and proper maintenance. Regularly inspect the oil level and quality, and replace it when dirty or degraded. Use OEM (original equipment manufacturer) parts for replacements, as these ensure the best fit and performance. Maintaining proper oil levels and ensuring the engine remains clean and free of debris can significantly reduce the risk of leaks. Visit our engine parts store for high-quality components.

5. Excessive Vibration and Noise

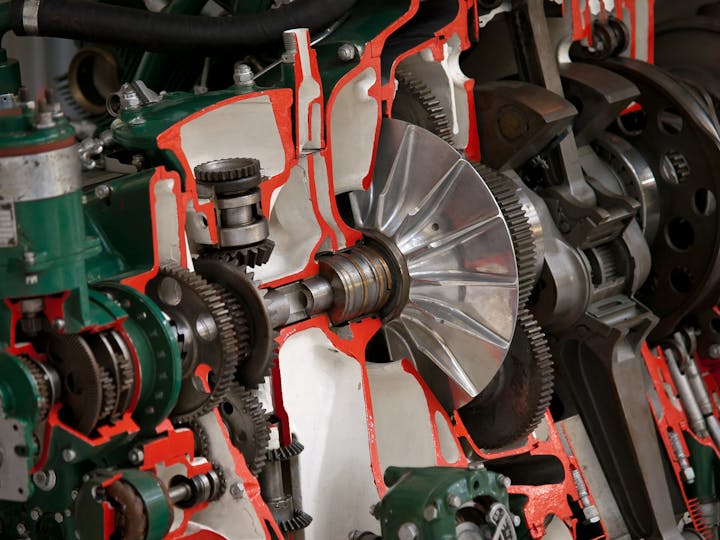

Excessive vibration and noise can indicate serious underlying issues in Kohler horizontal shaft engines. These problems often stem from loose or damaged engine mounts, imbalanced rotating parts like flywheels, or internal engine wear. Ignoring these signs can lead to further damage and reduced engine efficiency.

Start by inspecting the engine mounts. Loose or damaged mounts can cause vibrations and increase noise levels. Tighten the mounts or replace them if necessary. Next, check the rotating parts for balance. Misaligned pulleys or flywheels can cause uneven vibrations. Adjust or balance these components to minimize vibration. If the issue persists, inspect the internal engine components for wear, such as connecting rods, pistons, or bearings. Repairs or replacements may require professional assistance.

Regular maintenance is essential to prevent excessive vibration and noise. Ensure that all engine components are properly aligned and securely fastened. Avoid running the engine at extreme speeds for prolonged periods, as this can exacerbate wear and tear. If vibrations and noise become unmanageable, seek professional help to diagnose and resolve the problem. For replacement parts or expert service, explore our tractor seats and accessories.

Maintenance Tips to Prevent Problems

Preventive maintenance is key to extending the life of your Kohler horizontal shaft engine and ensuring optimal performance. Proper care not only prevents breakdowns but also improves efficiency, saving you time and money in the long run. Here are some detailed tips to maintain your engine effectively:

-

Follow a Regular Maintenance Schedule:

Create a maintenance checklist based on the engine manual. Routine tasks such as oil changes, air filter replacements, and fuel system checks should be done at specified intervals. For example, replace the engine oil every 25-50 hours of use or as recommended by Kohler.

-

Use High-Quality Fuel and Oil:

Always use fresh, high-grade fuel to minimize the risk of deposits and clogging in the carburetor. Similarly, opt for Kohler-recommended oil to ensure optimal lubrication and performance under various operating conditions.

-

Inspect Components Regularly:

Pay attention to the air filter, fuel filter, spark plugs, and cooling fins. A dirty air filter can reduce airflow, leading to overheating and loss of power. Check for wear and tear, replacing parts as needed to prevent more significant issues.

-

Keep the Engine Clean:

Dirt and debris can accumulate on cooling fins and other components, causing the engine to overheat. Regularly clean the engine exterior with compressed air or a soft brush to maintain proper airflow.

-

Proper Storage:

Store the engine in a dry, clean place away from moisture and dirt when not in use. For long-term storage, drain the fuel system and add a fuel stabilizer to prevent fuel degradation.

-

Monitor Engine Load:

Avoid overloading the engine. Overworking it for prolonged periods can cause excessive wear and overheating. Use the equipment within its designed capacity.

By implementing these maintenance tips, you can keep your Kohler engine running smoothly and reduce the likelihood of costly repairs.

Kohler Engine Maintenance Table

Proper maintenance involves following a structured schedule to ensure all components are in optimal condition. Below is a detailed table highlighting essential maintenance tasks, their frequency, and additional notes for Kohler horizontal shaft engines:

|

Maintenance Task |

Frequency |

Detailed Notes |

|

Check oil levels |

Before each use |

Use a dipstick to check the oil level and add Kohler-recommended oil if necessary. |

|

Change engine oil |

Every 25-50 hours |

Replace the oil more frequently in dusty or extreme conditions. |

|

Clean or replace air filters |

Monthly or as needed |

Check for clogs and replace filters if cleaning doesn't restore airflow. |

|

Inspect spark plugs |

Every 100 hours |

Look for fouling or wear. Replace with Kohler OEM plugs for best performance. |

|

Inspect and clean fuel lines |

Annually |

Remove debris or sediment from lines. Replace damaged or cracked lines. |

|

Clean cooling fins |

Quarterly |

Use compressed air to clear debris and prevent overheating. |

|

Check fuel quality |

As needed |

Use fresh, high-quality fuel. Add stabilizers for long-term storage. |

Why Choose Kohler Horizontal Shaft Engines?

Kohler horizontal shaft engines are renowned for their reliability, power, and versatility, making them a preferred choice across various industries in the USA. From lawnmowers and generators to pressure washers and construction equipment, these engines provide dependable performance.

Key Advantages of Kohler Horizontal Shaft Engines:

-

Durability:

Kohler engines are designed with high-quality materials that withstand extreme conditions. Features like cast-iron cylinder liners and high-performance components ensure long-lasting operation.

-

Ease of Maintenance:

Kohler engines are user-friendly and designed with accessibility in mind. Maintenance tasks like oil changes, air filter replacements, and spark plug inspections are simple, even for beginners.

-

Performance:

These engines offer excellent power output and efficiency, making them ideal for heavy-duty applications. Their advanced technology ensures consistent performance, even under demanding conditions.

-

Fuel Efficiency:

Kohler's efficient design minimizes fuel consumption while maximizing power. This reduces operational costs over the engine's lifespan.

-

Wide Range of Applications:

Kohler horizontal shaft engines are versatile and suitable for various tasks, including powering agricultural machinery, construction equipment, and recreational vehicles.

-

Support and Availability:

Kohler has a vast network of service centers and authorized dealers across the USA. This ensures you have access to replacement parts, expert advice, and maintenance support when needed.

Why Buy From Us?

At MO Small Engine Sales, we offer a wide range of Kohler engines and accessories to suit your needs. Browse our collections for horizontal shaft engines, vertical shaft engines, and tractor seats. Our products are sourced directly from Kohler, ensuring authenticity and quality.

By choosing Kohler, you invest in an engine that delivers exceptional value, durability, and performance, making it a reliable partner for all your equipment needs.

Conclusion

Understanding the common problems with Kohler horizontal shaft engines and their fixes can keep your equipment running smoothly. Regular maintenance, high-quality parts, and professional repairs when necessary are key to prolonging the life of your engine. For expert advice or replacement engines, visit MO Small Engine Sales.

Frequently Asked Questions (FAQs)

1. What are the most common problems with Kohler horizontal shaft engines?

The most common issues include starting problems, engine overheating, loss of power, oil leaks, and excessive vibration and noise. These issues can often be prevented with regular maintenance and proper care.

2. How can I fix starting issues with my Kohler horizontal shaft engine?

To fix starting problems, check the battery voltage, inspect and replace spark plugs if needed, clean or replace the carburetor, and flush clogged fuel lines. Ensuring proper maintenance and using high-quality fuel can help prevent these issues.

3. Why is my Kohler engine overheating, and how can I fix it?

Overheating can be caused by clogged cooling fins, low oil levels, or excessive workload. To fix it, clean the cooling fins, check oil levels and replace it with the recommended type, and avoid overloading the engine. Regular cleaning and maintenance help prevent this issue.

4. How can I prevent oil leaks in my Kohler engine?

Oil leaks can be caused by damaged gaskets, seals, or cracks in the engine casing. To fix it, replace damaged gaskets or seals, and ensure you're using the correct oil type and amount. Regular oil checks and maintenance can also help prevent leaks.

5. What maintenance should I perform to keep my Kohler engine running smoothly?

Regular tasks include checking oil levels before each use, changing oil every 25-50 hours, inspecting air filters monthly, and cleaning cooling fins quarterly. Always use high-quality fuel and oil, and store the engine properly when not in use to extend its lifespan.